Determination of the optimal content of zirconium in the 16crzr alloy for provide stable high values of mechanical properties

M. S. Konovalovab,

G. V. Sapozhnikovcb,

T. I. Shalaevad a Kalashnikov Izhevsk State Technical University, Izhevsk, Russia

b JSC ęResearch Institute of metallurgical technologyĽ, Izhevsk, Russia

c Physical-Technical Institute, Ural Branch of the Russian Academy of Sciences, Izhevsk, Russia

d Research Institute of mechanical engineering, Lower Salda, Russia

Abstract:

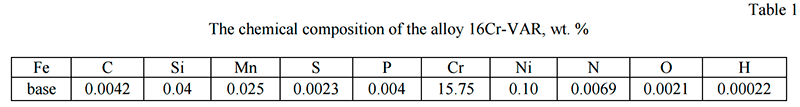

Three bars from the alloy 16CrZr have been prepared for the present investigation. The bars differ in the content of zirconium: bar № 1 - 0.15 wt. % Zr; bar № 2 - 0.12 wt. % Zr; bar № 3 - 0.04 wt. % Zr. The initial alloy 16CrZr-VAR (the chemical composition is given in Table 1 has been alloyed with zirconium of the grade E100 in vacuum. The bars have been prepared by extrusion.

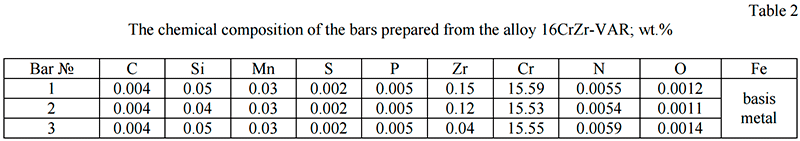

The chemical analysis shows that all the controlled chemical elements are distributed uniformly throughout the

bulks of the three bars. The chemical composition of the prepared bars is presented in Table 2.

The investigation of the microstructure of the prepared bars has been conducted and the mechanical properties of

the bars such as impact resistance, ultimate strength, yield strength, unit elongation and reduction of cross-sectional area have been tested. It is shown that the reason of the previously obtained inconsistent values of the mechanical properties (the value of impact resistance was about 15 kgf

$\cdot$m/cm

$^2$) is the over-alloying of the alloy with zirconium leading to the formation of intermetallic compounds of the Zr(Fe

$_2$Cr

$_2$) type which are hard and brittle Laves phases by their nature.

It has also been established that for providing of consistent improved values of the mechanical properties of the alloy 16CrZr it is necessary that during smelting zirconium should be introduced in the amount providing the fixation of the total nitrogen in nitrides; however, this amount should not be sufficient for the formation of intermetallic compounds of the Zr(Fe

$_2$Cr

$_2$) type.

It is established that the optimal content of zirconium in the alloy 16CrZr can be calculated according to the

\begin{equation*}

C(Zr) = \frac{C(N_2) \cdot n(Zr) \cdot M(Zr)}{n(N_2) \cdot M(N_2)}

\end{equation*}

where C(Zr) is the zirconium weight fraction in the alloy, %; C(N

$_2$) is the nitrogen weight fraction in the alloy, %;

n(Zr) is the coefficient showing the zirconium amount entering the reaction; M(Zr) is the zirconium molar mass,

g/mol.; n(N

$_2$) is the coefficient showing the nitrogen amount entering the reaction; M(N

$_2$) is the nitrogen molar mass, g/mol.

Keywords:

16’÷, mechanical properties, toughness, 16CrZr, Laves phases, microstructure.

UDC:

67.014:67.017:67.02:538.911